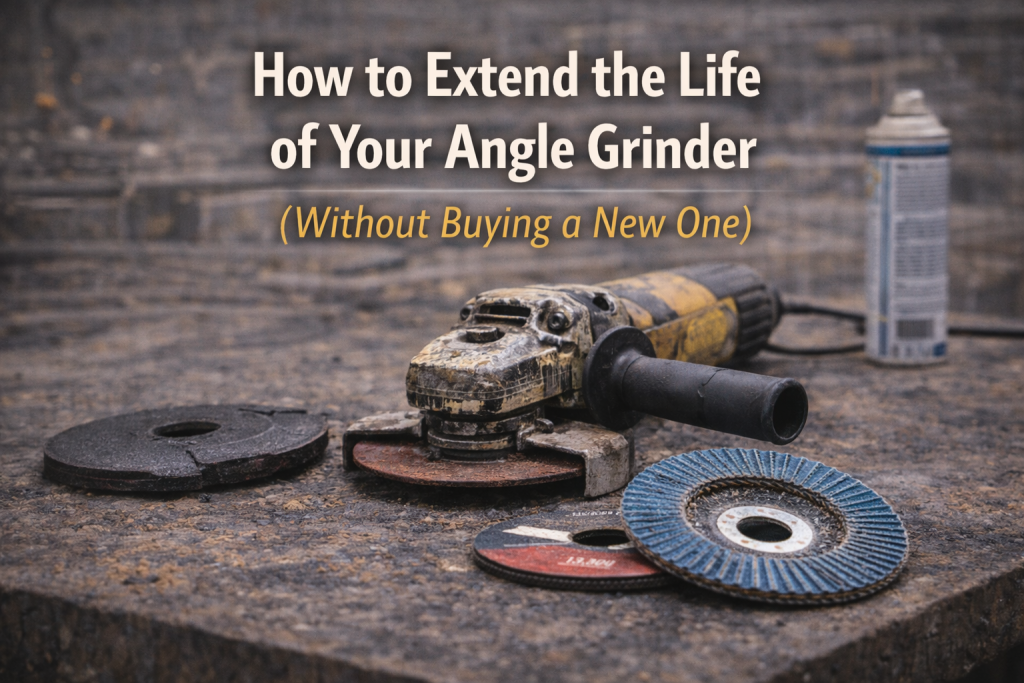

How to Extend the Life of Your Angle Grinder (Without Buying a New One)

Angle grinders are some of the hardest-working tools on any job site—and also some of the most abused. Most grinders don’t fail because they’re poorly made. They fail because of heat, vibration, dirt, and bad habits that quietly shorten their …

Read More

Abrasive Wheel Safety: What OSHA Actually Cares About (And What Most Shops Get Wrong)

Most shops think abrasive wheel safety is about wearing gloves and safety glasses. That’s part of it—but it’s not what OSHA focuses on first. The majority of citations and injuries tied to grinders come down to setup, ratings, and misuse, …

Read More

How Improper Grinding Destroys Bearings (And How to Prevent It)

Most people blame grinders when tools fail early. In reality, the grinder is usually the victim. Improper grinding techniques generate heat, vibration, and side-loading that quietly destroy bearings long before the motor gives out. At CEM Industrial Supply, we see …

Read More

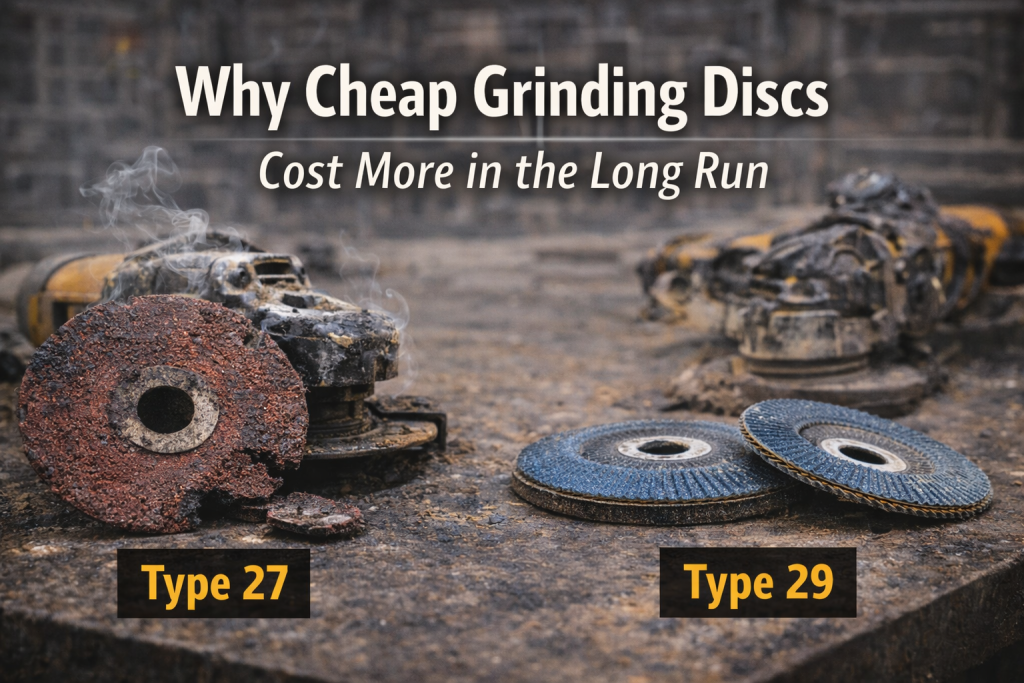

Why Cheap Grinding Discs Cost More in the Long Run

At first glance, a grinding disc is a grinding disc. They’re round, abrasive, and they spin fast. So when a cheaper option is sitting on the shelf, it’s tempting to grab it and move on. The problem is that low-cost …

Read More

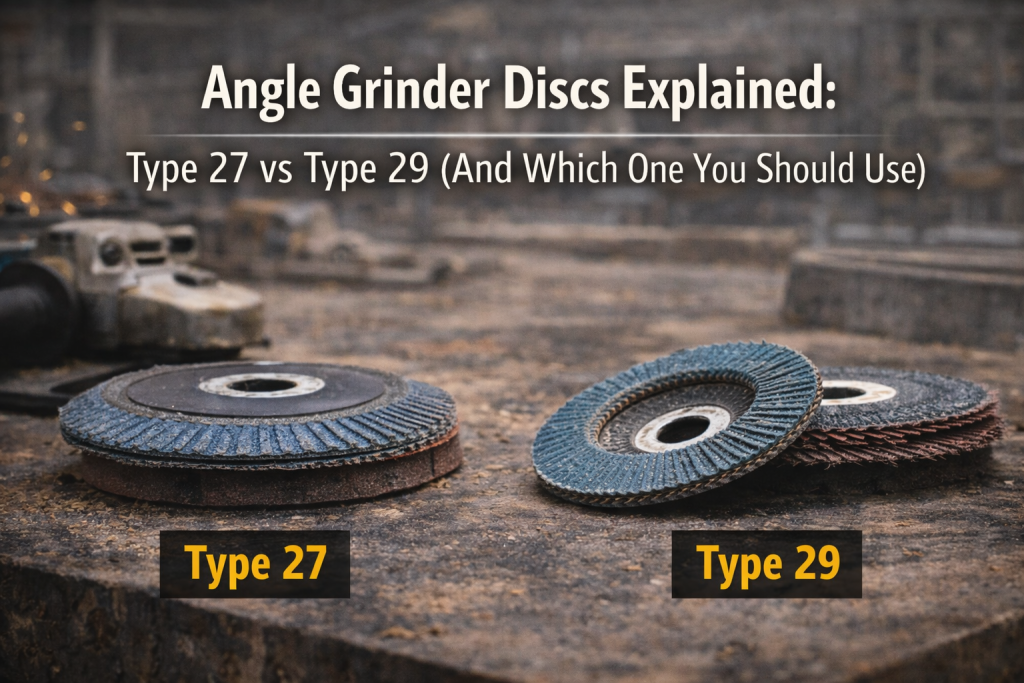

Angle Grinder Discs Explained: Type 27 vs Type 29 (And Which One You Should Use)

Angle grinder discs aren’t one-size-fits-all. Two discs can look nearly identical and perform very differently depending on how they’re built. One of the most misunderstood differences on the job site is Type 27 vs Type 29 discs. Using the wrong …

Read More

How to Choose the Right Abrasive for Metal, Steel, and Stainless

Not all abrasives are interchangeable. Using the wrong disc, wheel, or belt doesn’t just slow you down—it overheats material, ruins finishes, and shortens tool life. The right abrasive cuts faster, runs cooler, and produces better results with less effort. At …

Read More