If you’ve ever had a screw cam out, strip instantly, or refuse to come loose even though you’re using the “right” size Phillips screwdriver, there’s a good chance the problem isn’t your technique — it’s the screw type.

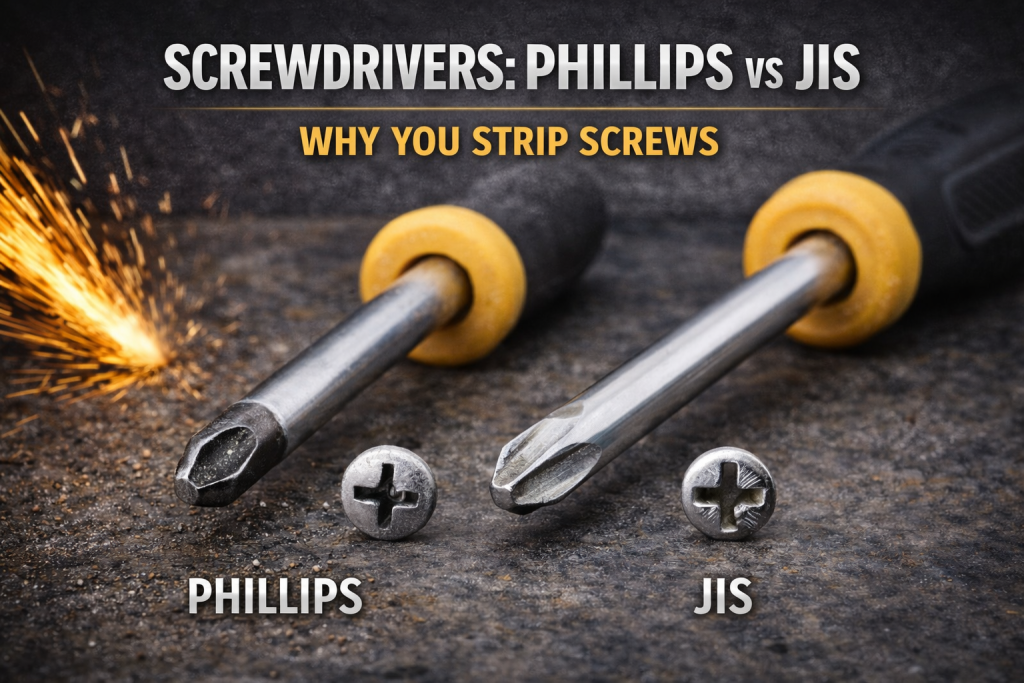

Phillips and JIS screws look almost identical, but they are not the same. Using a Phillips screwdriver on a JIS screw is one of the most common reasons screws strip, especially on motorcycles, equipment, and imported machinery.

This guide explains the difference between Phillips and JIS screwdrivers, how to identify each screw type, and how to stop destroying fasteners.

Why Screwdriver Type Matters

Using the wrong screwdriver affects:

- Torque transfer

- Cam-out (the bit slipping out)

- Screw head damage

- Fastener removal success

- Tool and fastener lifespan

Most stripped screws aren’t caused by overtightening — they’re caused by cam-out from mismatched drivers.

Phillips Screwdrivers: Designed to Cam Out

Phillips screws were intentionally designed to cam out under high torque. This was a feature, not a flaw, meant to prevent over-tightening in early assembly lines.

Key characteristics:

- Tapered flanks

- Shallow engagement

- Designed to slip under load

Best uses:

- General construction

- Wood screws

- Household fasteners

- Applications where over-torque is a concern

Limitations:

- Cam-out under higher torque

- Prone to stripping

- Poor choice for stubborn or seized fasteners

Phillips screwdrivers work fine for light-duty fastening, but they are not ideal for high-torque or precision applications.

JIS Screwdrivers: Full Engagement, No Cam-Out

JIS (Japanese Industrial Standard) screws are designed for full engagement between the driver and the screw head. They do not cam out the way Phillips screws do.

Key characteristics:

- Straighter flanks

- Deeper engagement

- Designed to stay seated under torque

Best uses:

- Motorcycles

- Automotive components

- Power equipment

- Industrial machinery

- Imported equipment

Strengths:

- Better torque transfer

- Less cam-out

- Reduced stripping

- Better control

Using a Phillips screwdriver in a JIS screw prevents full engagement, which causes slipping and rapid stripping.

How to Identify JIS vs Phillips Screws

Visual clues:

- JIS screws often have a small dot or mark near the cross

- Phillips screw slots are more rounded

- JIS slots appear sharper and deeper

Practical test:

- If a Phillips driver feels loose or rocks slightly, it’s likely a JIS screw

- A proper JIS driver will seat firmly with no wobble

Many people unknowingly strip JIS screws simply because they don’t realize a different standard exists.

Why Screws Strip So Easily

Common causes include:

Wrong driver type

Using Phillips on JIS screws causes cam-out immediately.

Worn screwdriver tips

Rounded tips slip even in correct screws.

Too much downward force

Forcing the driver increases cam-out instead of grip.

Impact use on wrong screws

Impact drivers with Phillips bits strip fasteners quickly if mismatched.

Corrosion or thread lock

Seized screws require breaking torque first, not more speed.

How to Stop Stripping Screws

Use the correct standard

Match Phillips to Phillips and JIS to JIS.

Replace worn drivers

A sharp tip grips better and transfers torque properly.

Break fasteners loose slowly

Use steady pressure instead of speed.

Use hand tools first

Especially on seized or delicate fasteners.

Keep JIS drivers in your toolbox

If you work on imported equipment, they pay for themselves quickly.

Side-by-Side Comparison

Phillips

Designed for: Cam-out protection

Torque transfer: Moderate

Stripping risk: Higher

Best for: Light-duty fastening

JIS

Designed for: Full engagement

Torque transfer: High

Stripping risk: Lower

Best for: Machinery and equipment

Common Mistake We See

People assume all cross-head screws are Phillips. On Japanese equipment, this almost guarantees stripped screws, broken bits, and frustration.

Once a JIS screw is stripped, removal becomes far more difficult than simply using the right driver from the start.

Final Takeaway

Phillips and JIS screwdrivers are not interchangeable. Phillips drivers are designed to cam out, while JIS drivers are designed to stay engaged under torque. Using the wrong one is the main reason screws strip so easily.

If you work on motorcycles, power equipment, or imported machinery and keep stripping screws, the fix may be as simple as switching screwdriver standards.