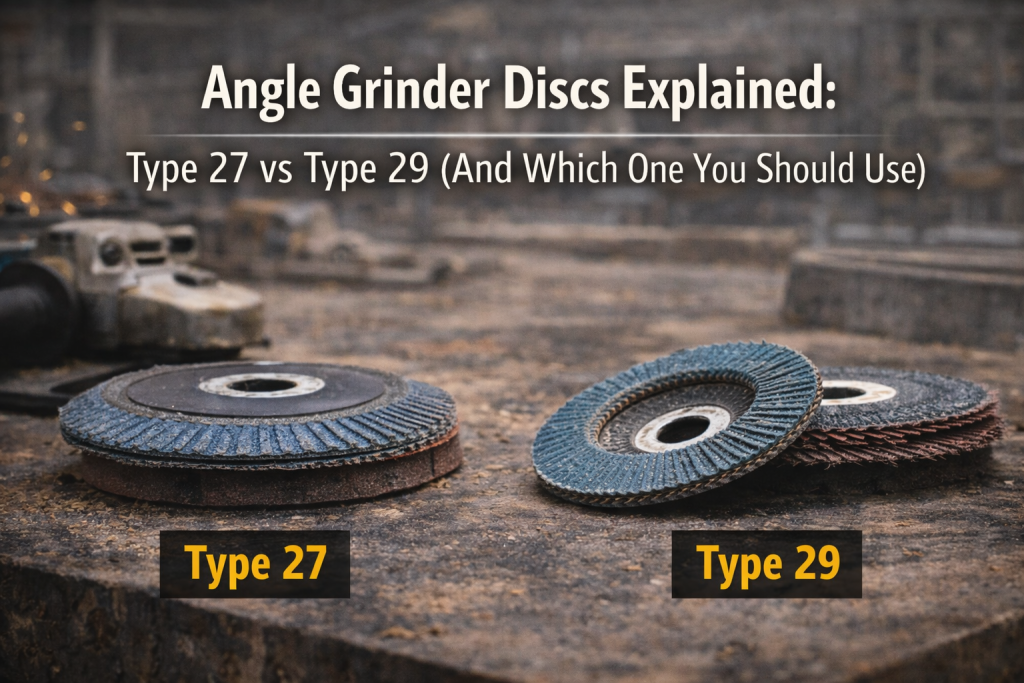

Angle grinder discs aren’t one-size-fits-all. Two discs can look nearly identical and perform very differently depending on how they’re built. One of the most misunderstood differences on the job site is Type 27 vs Type 29 discs.

Using the wrong one leads to slower work, poor finishes, and unnecessary grinder wear. Here’s how to choose correctly.

What Type 27 Discs Are Designed For

Type 27 discs have a flat or slightly depressed profile. They’re designed to be used at shallow angles, typically between 0 and 15 degrees.

Type 27 discs are best for:

- Flat surface grinding

- Light blending

- Edge work and cleanup

- Controlled material removal

Because they sit flatter against the work surface, Type 27 discs offer more precision and are easier to control when finish quality matters.

What Type 29 Discs Are Designed For

Type 29 discs have a more aggressive angled profile. They’re designed to be used at steeper angles, usually between 15 and 35 degrees.

Type 29 discs are best for:

- Aggressive grinding

- Heavy stock removal

- Working on weld seams

- Faster material removal

The angled design allows more abrasive contact, which removes material faster but with less surface control.

Speed vs Finish: The Real Difference

Type 29 discs remove material faster. Type 27 discs leave a cleaner, more consistent finish.

If speed is the priority, Type 29 gets the job done quickly. If control and surface quality matter, Type 27 is usually the better choice.

Many professionals keep both on hand and switch based on the stage of the job.

Grinder Wear and Operator Fatigue

Using the wrong disc profile forces operators to compensate with awkward angles and extra pressure.

Type 29 discs:

- Reduce grinding time

- Increase aggressiveness

- Can cause more fatigue if overused

Type 27 discs:

- Offer smoother control

- Reduce vibration

- Are easier on bearings and wrists

Matching disc type to task protects both the tool and the operator.

Safety and Disc Selection Tips

Always verify RPM ratings and disc compatibility. Never force a disc beyond its intended angle of use.

Using Type 29 discs flat or Type 27 discs aggressively shortens disc life and increases the risk of failure.

The Bottom Line

Type 27 and Type 29 discs serve different purposes. Choosing the right profile improves speed, finish quality, and tool longevity.

If you’re unsure which disc fits your application, CEM Industrial Supply can help match the disc to your grinder, material, and workload.