One of the hardest calls in motor repair is deciding whether to rewind or replace. Rewinding can save money and preserve custom motors — but in the wrong situation, it becomes a sunk cost that leads to repeat failure.

This guide gives you a practical, step-by-step checklist to decide when replacement is the smarter move.

Why This Decision Matters

Choosing incorrectly can result in:

- Spending more than a new motor costs

- Extended downtime

- Repeat failures

- Reduced efficiency

- Wasted labor and materials

The right decision balances cost, reliability, efficiency, and downtime — not emotion or habit.

The Core Rule of Thumb

If the total rewind cost approaches 60–70% of the replacement cost for a standard motor, replacement usually makes more sense.

But cost alone is not the full story.

Decision Checklist: Replace or Rewind?

Work through this checklist in order.

1. Motor Size and Horsepower

Small motors are rarely good rewind candidates.

Replace if:

- Fractional HP to ~10 HP

- Standard frame

- Off-the-shelf availability

Rewind if:

- Large horsepower motor

- Specialty frame or configuration

- Long replacement lead times

Small motors are cheaper to replace than rewind almost every time.

2. Motor Age and Design

Older motors may not justify investment.

Replace if:

- Motor is obsolete

- Efficiency class is outdated

- Replacement is readily available

Rewind if:

- Motor is modern

- Inverter-duty or severe-duty

- Built for harsh environments

Rewinding an outdated design often locks in inefficiency.

3. Efficiency and Energy Costs

Energy costs often exceed repair costs over time.

Replace if:

- Motor is pre-premium efficiency

- Runs continuously

- Energy savings justify upgrade

Rewind if:

- Premium efficiency motor

- Efficiency will be maintained

- Downtime costs outweigh energy savings

Efficiency upgrades matter most on continuously running motors.

4. Core and Stator Condition

This is a major deciding factor.

Replace if:

- Core lamination damage exists

- Hot spots are present

- Core losses are excessive

Rewind if:

- Core tests good

- No lamination damage

- Insulation failure only

A damaged core often makes rewinding uneconomical or unreliable.

5. Cause of Failure

Understanding why the motor failed is critical.

Replace if:

- Chronic overheating occurred

- Voltage imbalance was severe and prolonged

- Moisture contamination is extensive

- Multiple past rewinds exist

Rewind if:

- Single isolated failure

- Insulation breakdown only

- Bearings or mechanical issues caused the failure

Repeating the same rewind without fixing the root cause guarantees another failure.

6. Application and Environment

Environment matters as much as motor condition.

Replace if:

- Original motor was not suited for environment

- Frequent dust, moisture, or chemical exposure

- Washdown or farm duty conditions exist

Rewind if:

- Motor design matches environment

- Proper protection is in place

- Environmental cause has been corrected

Sometimes the problem isn’t the motor — it’s where it’s installed.

7. Downtime and Lead Time

Time is often more valuable than repair cost.

Replace if:

- New motor is available immediately

- Downtime cost is high

- Repair turnaround is long

Rewind if:

- Replacement lead time is long

- Motor is critical or custom

- Expedited rewind is available

Production losses often outweigh repair savings.

8. History of Previous Repairs

Repeated rewinds reduce reliability.

Replace if:

- Motor has been rewound multiple times

- Failure intervals are shortening

- Performance is declining

Rewind if:

- First rewind

- Strong repair history

- Known root cause addressed

Each rewind stresses the core and insulation system.

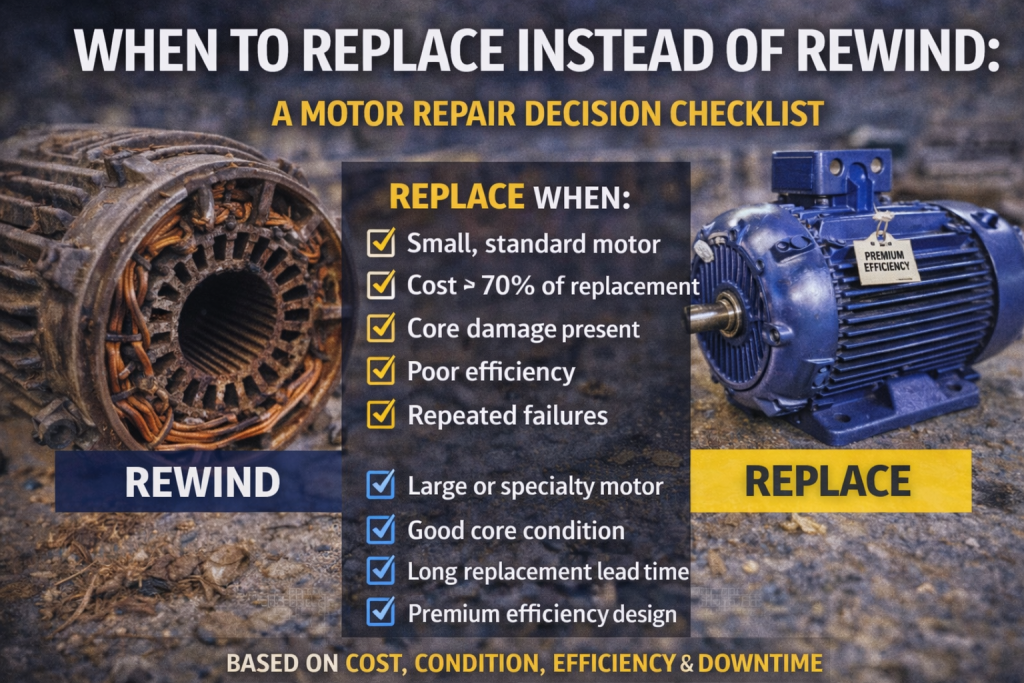

Quick Decision Matrix

Replace when:

- Small, standard motor

- Rewind cost > 70% of replacement

- Core damage present

- Poor efficiency

- Repeated failures

Rewind when:

- Large or specialty motor

- Good core condition

- Long replacement lead time

- Premium efficiency design

- First-time insulation failure

Common Mistakes We See

Rewinding small motors out of habit

Ignoring energy efficiency gains

Repairing without fixing root causes

Assuming rewinding is always cheaper

Letting downtime drive rushed decisions

The cheapest option upfront is not always the cheapest long-term.

How a Good Shop Helps You Decide

A reputable motor shop should:

- Test the core

- Explain failure causes

- Compare repair vs replacement honestly

- Factor in efficiency and downtime

- Recommend replacement when appropriate

If replacement is never suggested, that’s a red flag.

Final Takeaway

Rewinding is a powerful tool — but not always the right one. When motors are small, inefficient, damaged, or repeatedly failing, replacement is often the smarter, safer investment.

Use this checklist before committing money to a rewind. A clear decision upfront prevents repeat failures and wasted cost later.