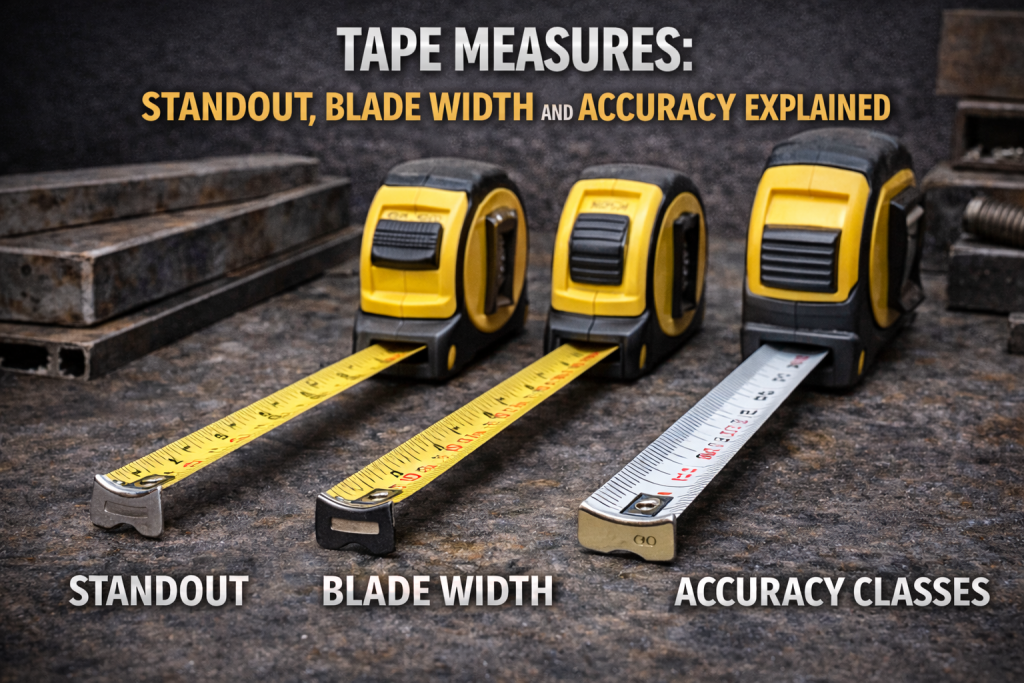

Not all tape measures measure the same — at least not in practice. Standout distance, blade width, and accuracy class all affect how usable, accurate, and frustrating a tape measure is on the job.

If your tape keeps collapsing, flexing, or giving inconsistent measurements, the issue usually isn’t the brand — it’s the specs.

This guide breaks down what standout really means, why blade width matters, and how accuracy classes affect real-world measuring.

Why Tape Measure Specs Matter

Tape measures impact:

- One-person measuring

- Accuracy over distance

- Durability

- Readability

- Jobsite efficiency

A cheap tape that collapses or bends forces two-person measuring and increases errors — which costs time and material.

Standout: The Most Important Feature

Standout is how far a tape blade can extend horizontally before it collapses under its own weight.

Why standout matters:

- Allows one-person measuring

- Critical for framing and layout

- Reduces re-measuring

- Improves speed and accuracy

Typical standout ranges:

- 6–8 ft: Light-duty tapes

- 8–10 ft: General construction

- 10–13+ ft: Professional framing tapes

Wider blades and stronger blade curvature increase standout. If your tape constantly folds over, it likely has insufficient standout for your work.

Blade Width: Strength and Control

Blade width directly affects rigidity, durability, and readability.

Common blade widths:

- 3/4″ – Light-duty, compact tapes

- 1″ – General-purpose tapes

- 1-1/4″ – Heavy-duty framing tapes

- 1-3/8″+ – Professional-grade tapes

Wider blades:

- Stand farther without collapsing

- Resist twisting

- Are easier to read

- Last longer under jobsite abuse

Narrow blades are fine for light work, but they struggle with long spans and outdoor conditions.

Blade Coating and Durability

Blade coatings protect against:

- Abrasion

- Rust

- Fading

- Dirt buildup

Common coatings include nylon or polymer overlays. These extend blade life and keep markings readable over time, especially in dusty or wet environments.

Accuracy Classes: Why They Exist

Accuracy class defines how close a tape measure is to true measurement over its length. This is especially important in layout, finish work, and precision fabrication.

Common accuracy classes:

- Class I: Highest accuracy (precision work)

- Class II: Standard professional accuracy

- Class III: General-purpose accuracy

Most professional tape measures fall into Class II. Class I tapes are typically used in surveying, machining, or specialized layout work.

For framing and general construction, Class II is more than sufficient. Accuracy problems usually come from damaged hooks or worn blades, not class rating.

The Hook Matters More Than You Think

The end hook is designed to move slightly to compensate for inside and outside measurements.

Common hook problems:

- Bent hooks

- Loose rivets

- Excessive play

- Debris buildup

A damaged hook causes inaccurate readings no matter how good the tape is. If your measurements feel inconsistent, check the hook before blaming the tape.

Common Mistakes We See

Choosing compact tapes for framing

Small tapes lack standout and slow down layout work.

Ignoring blade width

Narrow blades collapse and twist under real job conditions.

Using damaged tapes

Bent hooks and worn blades introduce measurement errors.

Overpaying for features you don’t need

Extra-long tapes with poor standout don’t solve measuring problems.

How to Choose the Right Tape Measure

Choose a high-standout, wide-blade tape if:

- You measure alone

- You do framing or layout

- You work outdoors or overhead

Choose a compact tape if:

- You do finish work

- Measurements are short

- Portability matters

Check accuracy class if:

- You do precision layout

- Measurements must match across tools

- Tolerances matter

Final Takeaway

Standout, blade width, and accuracy class determine how usable and reliable a tape measure is — far more than brand name or length alone. A tape that stands out farther, resists twisting, and maintains hook accuracy saves time and reduces mistakes.

If your tape measure is fighting you instead of helping, it’s probably the wrong spec for the job.