Electric motors are the heartbeat of your operation—whether you’re running a farm irrigation system, a factory conveyor, or a jobsite compressor. But like any piece of equipment, motors wear out. Bearings fail, windings short, insulation breaks down, and before you know it, your motor is running hot, tripping breakers, or just refusing to start.

At CEM Industrial Supply, we don’t just sell motors—we repair them. And knowing when a motor can be repaired (or rewound) versus when it makes more sense to replace it can save you a lot of downtime and dollars.

What Commonly Goes Wrong with Electric Motors?

- Bearing Failure – The most frequent issue. Bearings seize, grind, or loosen, causing noise, vibration, and eventual shaft damage.

- Overheating – Excessive loads, poor ventilation, or electrical issues cause insulation breakdown, shortening winding life.

- Electrical Shorts – Windings can short due to age, dirt, or overheating, leading to tripped circuits or dead motors.

- Moisture and Contamination – Dust, oil, and water wreak havoc on both electrical and mechanical components.

- Imbalance and Misalignment – Poor installation or belt tension issues lead to premature wear and vibration problems.

What’s Involved in Motor Repair?

Repairing a motor isn’t guesswork—it’s a process. Our motor techs go through steps like:

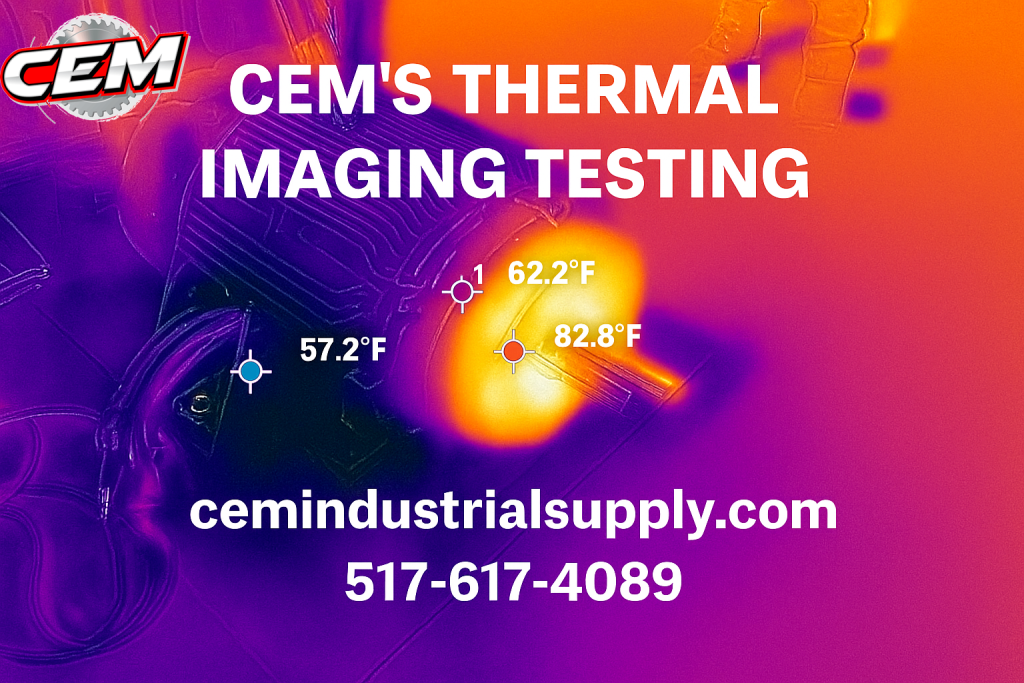

- Inspection & Testing – Checking insulation resistance, winding continuity, and vibration levels.

- Bearing Replacement – Swapping worn bearings with high-quality replacements to restore smooth operation.

- Rewinding – Stripping out failed windings, rewinding coils, and re-insulating to OEM or better specs.

- Machining & Balancing – Restoring shafts, housings, and ensuring the rotor is balanced for quiet, efficient operation.

- Final Testing – Running the motor under load to verify performance before it ever leaves our shop.

Rewind or Replace?

Here’s the million-dollar question: When is rewinding worth it—and when should you buy new?

- Rewind when the motor is large, specialized, or expensive to replace. Rewinding can restore it to like-new performance at a fraction of the cost.

- Replace when the motor is small, off-the-shelf, or when repair costs get close to new purchase price. Sometimes, new efficiency standards make upgrading the smarter move.

- Middle Ground – If your motor is borderline, our techs can run a cost-benefit analysis to help you decide.

What to Do Before Deciding

Before you pull the trigger on a new motor—or tear into an old one—call one of our Motor Techs at CEM Industrial Supply. We’ll evaluate:

- The motor’s age and application

- Energy efficiency vs. replacement options

- Cost of rewind/repair vs. new purchase

- Your downtime and urgency requirements

Sometimes a quick bearing swap gets you running again. Other times, replacing makes more sense long-term. Either way, we’ll give you an honest assessment.

Call CEM Before You Decide

At the end of the day, repairing or replacing a motor is about saving you time and money without cutting corners. Don’t guess—get expert advice.

Call us at 517-617-4089 to talk with a motor tech today.

Or stop by CEM Industrial Supply and let’s look at your motor together.