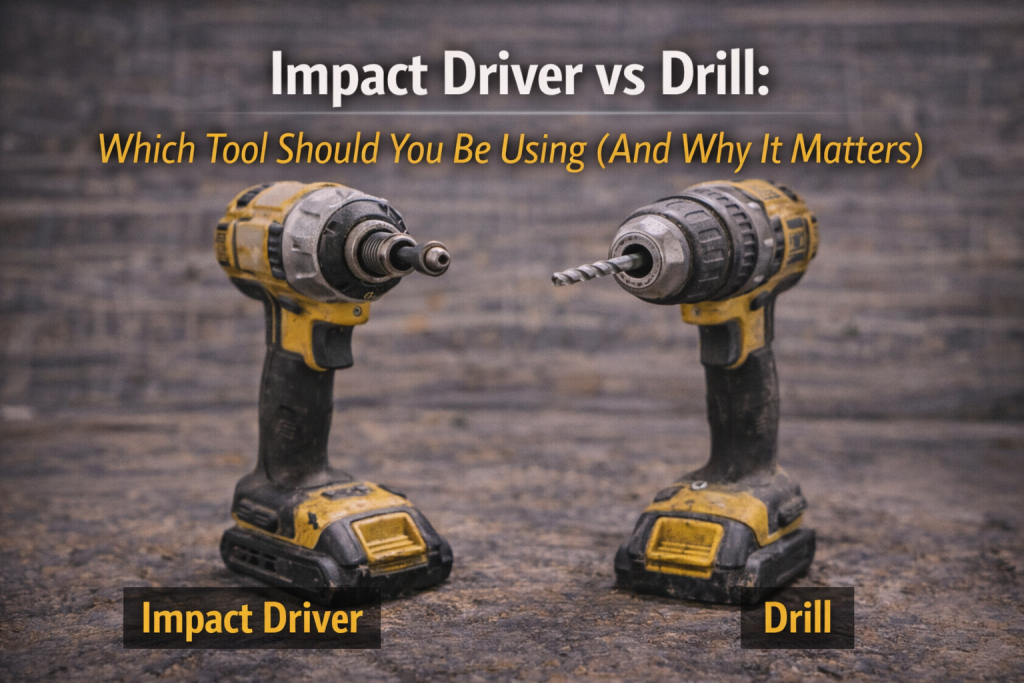

Impact drivers and drills look similar, use similar batteries, and often sit side by side in tool kits. That’s why they’re constantly misused. Using the wrong one leads to stripped fasteners, broken bits, and unnecessary tool wear.

At CEM Industrial Supply, this mix-up causes more frustration than almost any other power tool question. Here’s the clear difference.

What a Drill Is Designed to Do

Drills are designed for precision and control. They deliver steady rotational force and allow speed and torque adjustment.

Drills work best for:

- Drilling holes

- Driving screws into softer materials

- Precision fastening

- Using specialty attachments

Clutches on drills prevent overdriving fasteners and damaging materials.

What an Impact Driver Is Designed to Do

Impact drivers use rotational impacts to deliver short bursts of high torque.

Impact drivers work best for:

- Driving long screws

- Fastening lag bolts

- Working with dense materials

- Repetitive fastening tasks

They reduce wrist strain and are far less likely to cam out fasteners under load.

Why Impacts Strip Less (And Break More Bits)

Impact drivers don’t apply constant torque. Instead, they deliver force in pulses. This keeps the bit engaged while breaking resistance gradually.

However, using standard drill bits or low-quality driver bits in impact drivers leads to broken bits quickly. Impact-rated accessories are mandatory.

When a Drill Is the Better Choice

Drills outperform impact drivers when:

- Drilling clean, accurate holes

- Working with thin materials

- Using hole saws or step bits

- Precision matters

Using an impact driver for drilling often results in poor hole quality and broken bits.

When an Impact Driver Is the Better Choice

Impact drivers shine when:

- Driving fasteners all day

- Working with structural screws

- Fastening into metal or hardwood

- Speed matters more than finesse

They’re faster, easier on the user, and more efficient for fastening-heavy jobs.

Tool Wear and Longevity

Using the wrong tool increases wear:

- Drills suffer clutch and gearbox damage when over-torqued

- Impacts break non-rated bits and accessories

Matching the tool to the task extends tool life and reduces downtime.

The Bottom Line

Drills drill. Impact drivers drive. Using them interchangeably causes frustration, broken accessories, and tool damage.

If you’re unsure which tool fits your application—or which accessories are impact-rated—CEM Industrial Supply can help you choose the right setup the first time.