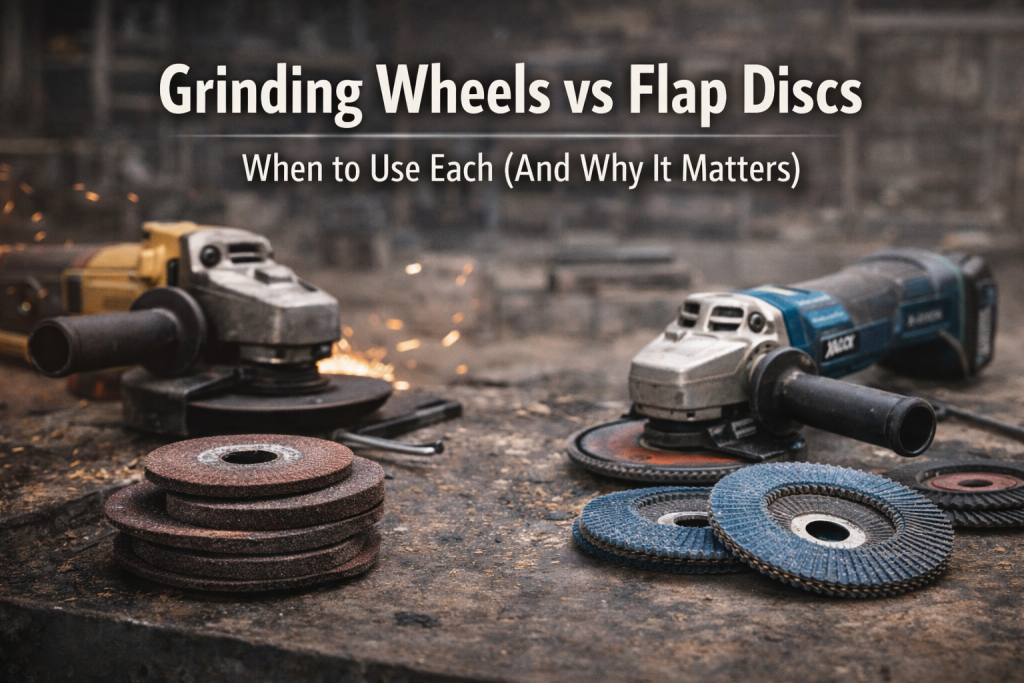

Grinding wheels and flap discs look similar at a glance, but they behave very differently in real-world use. Choosing the wrong one leads to slow material removal, excess heat, damaged parts, and worn-out grinders. Choosing the right one makes jobs faster, cleaner, and safer.

At CEM Industrial Supply, this is one of the most common counter questions we get. Here’s the clear, practical answer.

What Grinding Wheels Are Best At

Grinding wheels are designed for aggressive material removal. They are rigid, durable, and built to handle heavy pressure.

Grinding wheels excel at:

- Removing large amounts of metal quickly

- Grinding down welds

- Shaping steel and iron

- Working on thick or hardened materials

Because they don’t flex, grinding wheels transfer more vibration to the tool and operator. They also generate more heat, which can affect thin materials or precision parts.

Grinding wheels are the right choice when speed and material removal matter more than surface finish.

What Flap Discs Are Best At

Flap discs are made from layered abrasive flaps bonded to a backing plate. As the flaps wear down, fresh abrasive is exposed.

Flap discs excel at:

- Blending welds

- Surface finishing

- Light grinding and shaping

- Working on thinner materials

They remove material more smoothly and with less vibration. Heat buildup is lower, and the finished surface is cleaner and more controlled.

Flap discs are ideal when you need both grinding and finishing without switching tools.

Speed vs Control: The Real Difference

Grinding wheels remove material fast but leave a rougher surface. Flap discs remove material more slowly but offer better control and finish.

If you’re grinding structural steel, a grinding wheel saves time. If you’re working on stainless, sheet metal, or visible welds, flap discs usually produce better results with less rework.

Tool Wear and Safety Considerations

Using the wrong accessory stresses both the tool and the operator.

Grinding wheels:

- Increase vibration

- Accelerate bearing wear

- Require careful angle control

Flap discs:

- Reduce vibration

- Are more forgiving on angle

- Lower the risk of gouging

Always verify RPM ratings and use guards. Never force either accessory beyond its intended use.

Which Should You Keep on Hand?

Most professionals keep both.

Use grinding wheels for heavy stock removal and flap discs for blending and finishing. Switching accessories costs far less than replacing damaged parts or worn-out tools.

If you’re unsure which abrasive fits your application, CEM Industrial Supply can help you match the disc to the material, grinder, and job.