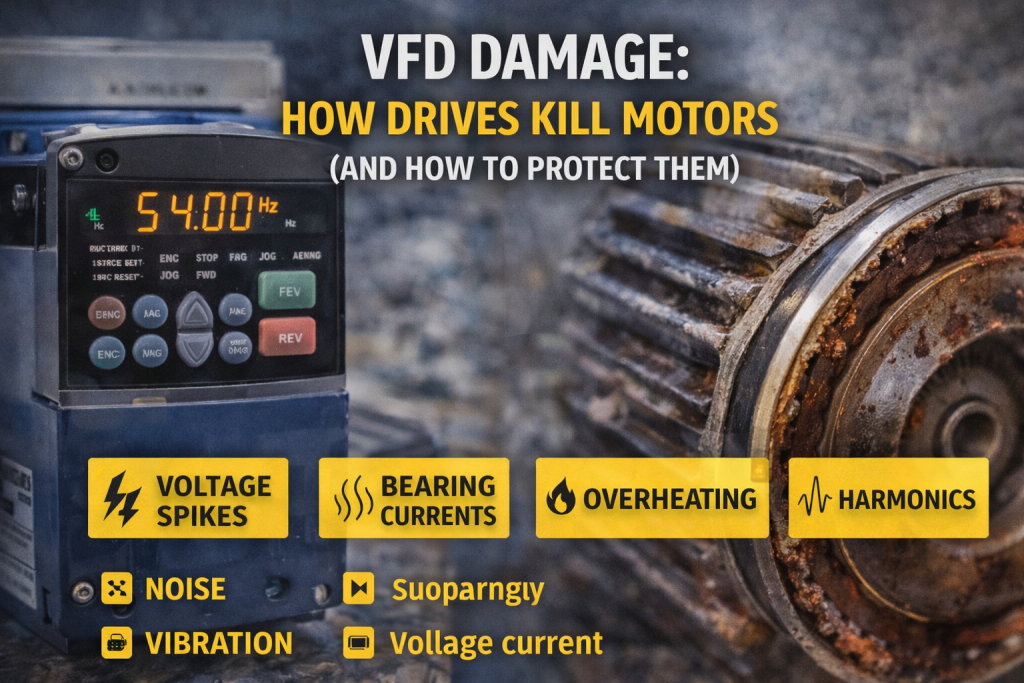

Variable Frequency Drives (VFDs) save energy, improve process control, and extend equipment flexibility — but they can also quietly destroy motors when installed or applied incorrectly. Many motor failures blamed on “bad motors” are actually caused by VFD-related electrical stress.

This article explains how VFDs damage motors, what symptoms to watch for, and how to protect motors so you get the benefits of a drive without shortening motor life.

Why VFDs Are Hard on Motors

Unlike utility power, VFDs do not supply a smooth sine wave. They rapidly switch voltage on and off to control speed, which creates electrical conditions motors were never originally designed to handle.

Key VFD-related stress factors include:

- High voltage spikes

- Rapid rise times (dv/dt)

- Harmonics

- Bearing currents

- Additional heat

These stresses compound over time and often cause premature failure.

1. Voltage Spikes and Insulation Breakdown

One of the biggest motor killers is voltage spike reflection.

What happens:

- VFDs generate fast-switching PWM voltage

- Long motor leads cause voltage reflections

- Peak voltage at the motor can exceed insulation limits

This leads to:

- Partial discharge

- Insulation erosion

- Ground faults

- Early winding failure

Symptoms:

- Repeated winding failures

- Low insulation resistance

- Failures shortly after rewind or replacement

2. dv/dt Stress on Windings

VFDs apply voltage extremely fast.

Why it matters:

- Older motors were designed for smooth sine waves

- Rapid rise times stress turn-to-turn insulation

- Weak spots fail first

This is especially damaging on:

- Older motors

- Rewound motors without inverter-duty insulation

- Motors with long cable runs

3. Bearing Currents and Electrical Fluting

VFDs can induce electrical currents through motor bearings.

What happens:

- Shaft voltage builds up

- Current discharges through bearings

- Microscopic pitting occurs

Over time this causes:

- Bearing noise

- Fluting patterns on races

- Premature bearing failure

Symptoms:

- High-pitched whining

- Bearing failures with no lubrication issues

- Vibration shortly after startup

4. Overheating at Low Speeds

Running motors slowly reduces cooling effectiveness.

Why:

- Shaft-mounted fans move less air

- Torque demand remains high

- Heat builds up internally

This causes:

- Insulation degradation

- Bearing grease breakdown

- Reduced motor life

Low-speed, high-torque applications are especially vulnerable.

5. Harmonics and Additional Heating

VFDs introduce harmonic currents that increase losses.

Results include:

- Higher winding temperatures

- Reduced efficiency

- Nuisance trips

- Shortened insulation life

Motors may appear properly sized but still overheat due to harmonic heating.

Common Signs of VFD-Related Motor Damage

Watch for:

- Repeated bearing failures

- Motors running hotter on VFDs than across-the-line

- Early insulation breakdown

- Electrical noise or whining

- Short motor life despite light loading

If failures follow VFD installation, the drive is often the root cause.

How to Protect Motors from VFD Damage

Use Inverter-Duty Motors

Inverter-duty motors feature:

- Improved insulation systems

- Better turn-to-turn protection

- Enhanced thermal ratings

They are designed to handle VFD stress long-term.

Install Output Filters

Common protection devices:

- dv/dt filters

- Sine wave filters

- Load reactors

These reduce voltage spikes and soften waveforms reaching the motor.

Control Motor Lead Length

Long cable runs amplify voltage reflections.

Best practice:

- Keep motor leads as short as possible

- Add filters when runs exceed manufacturer recommendations

Protect Bearings

Bearing protection options include:

- Insulated bearings

- Shaft grounding rings

- Conductive grease paths

These prevent destructive bearing currents.

Address Cooling at Low Speed

Solutions include:

- External blower kits

- Oversized motors

- Minimum speed limits in the VFD

Cooling must match torque demand.

Common Misconceptions

“VFDs are gentle on motors”

They reduce mechanical stress but increase electrical stress.

“If the motor spins, it’s fine”

Damage often occurs silently until failure.

“Only large motors need protection”

Small motors fail just as often on VFDs.

When Motors Fail After a VFD Install

If a motor fails shortly after VFD installation, always evaluate:

- Insulation class and condition

- Bearing condition and fluting

- Cable length and routing

- VFD parameters and switching frequency

- Presence (or absence) of output filtering

Replacing the motor without fixing the cause usually leads to repeat failure.

Final Takeaway

VFDs don’t kill motors by default — poor application does. Voltage spikes, bearing currents, overheating, and insulation stress silently shorten motor life when protection isn’t in place.

The right motor, proper filtering, bearing protection, and cooling turn a VFD from a motor killer into a long-term asset.