Single-phase and three-phase motors do the same job, but they fail in very different ways. Understanding how each motor type typically fails makes troubleshooting faster, prevents unnecessary rewinds, and helps you decide whether repair or replacement makes sense.

This guide breaks down the most common failures, early warning symptoms, and what usually kills each motor type first.

Why Motor Phase Type Matters

Motor phase type affects:

- Starting method

- Electrical stress

- Component count

- Failure likelihood

- Repair cost

Many motors are misdiagnosed simply because the technician assumes all motors fail the same way.

They don’t.

Single-Phase Motors: Common Failures and Symptoms

Single-phase motors are simpler electrically but rely on additional starting components, which are frequent failure points.

1. Capacitor Failure (Most Common)

Capacitors are the #1 failure in single-phase motors.

Symptoms:

- Motor hums but won’t start

- Motor starts only if spun by hand

- Tripped breakers on startup

- Weak or sluggish acceleration

- Swollen or leaking capacitor

Why it happens:

- Heat

- Voltage fluctuations

- Aging dielectric material

- Poor ventilation

Capacitors fail far more often than windings in single-phase motors.

2. Centrifugal Switch Failure

Older single-phase motors use a centrifugal switch to disengage the start circuit.

Symptoms:

- Loud clicking or grinding at startup

- Motor starts intermittently

- Motor stays in start winding too long

- Overheating shortly after start

Why it happens:

- Dirt and dust

- Mechanical wear

- Broken springs or contacts

When switches fail, motors often overheat quickly.

3. Overheating Due to Load or Cooling Issues

Single-phase motors are less efficient and run hotter by design.

Symptoms:

- Hot motor housing

- Thermal overload trips

- Burnt smell

- Shortened lifespan

Why it happens:

- Undersized motor

- Continuous duty beyond rating

- Blocked airflow

- Poor ambient conditions

Heat accelerates insulation failure rapidly in single-phase motors.

4. Winding Failure (Less Common, More Expensive)

Symptoms:

- Burnt odor

- Low insulation resistance

- Tripped breakers

- Motor won’t restart after cooling

Winding failure usually follows prolonged capacitor or switch problems.

Three-Phase Motors: Common Failures and Symptoms

Three-phase motors are electrically simpler and more robust — but when they fail, the cause is often external.

1. Voltage Imbalance and Single-Phasing

The most common killer of three-phase motors.

Symptoms:

- Motor runs hot

- Uneven phase amperage

- Reduced torque

- Nuisance overload trips

- Motor continues running after losing a phase

Why it happens:

- Loose connections

- Blown fuses

- Faulty contactors

- Utility supply issues

Even a small voltage imbalance dramatically increases heat.

2. Bearing Failure (Very Common)

Three-phase motors run smoothly, which masks bearing issues until damage is advanced.

Symptoms:

- Growling or rumbling noise

- High vibration

- Localized bearing heat

- Shaft play

- Sudden catastrophic failure

Why it happens:

- Poor lubrication

- Contamination

- Misalignment

- VFD-induced bearing currents

Bearings often fail long before windings.

3. VFD-Related Electrical Stress

Modern three-phase motors frequently operate on drives.

Symptoms:

- Repeated bearing failures

- Electrical fluting

- Insulation breakdown

- Premature winding failure

- High-pitched electrical noise

Why it happens:

- Voltage spikes

- dv/dt stress

- Bearing currents

- Inadequate filtering

Many “mystery failures” trace back to VFD application issues.

4. Winding Insulation Breakdown

Less common than bearing failure, but more costly.

Symptoms:

- Failed megger or surge test

- Tripped breakers

- Burnt insulation odor

- Motor won’t start or stalls under load

Often caused by:

- Chronic overheating

- Voltage imbalance

- Repeated overload

- Poor cooling

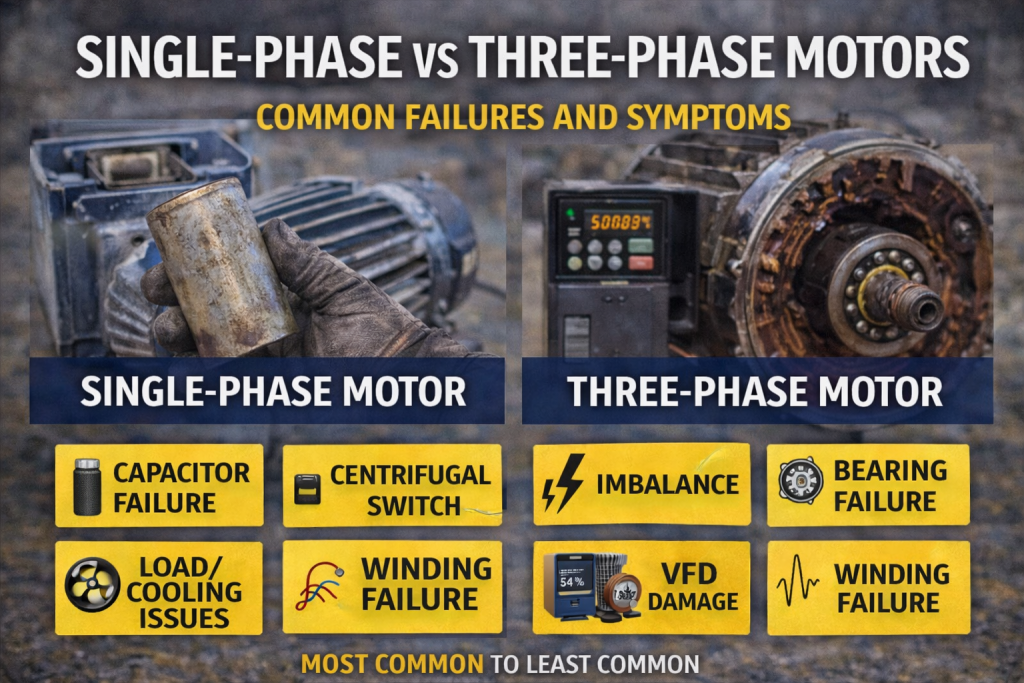

Side-by-Side Failure Comparison

Single-Phase Motors

Most common failure: Capacitors

Typical symptoms: Humming, no start

Repair cost: Low to moderate

Overheating risk: High

Three-Phase Motors

Most common failure: Bearings / voltage issues

Typical symptoms: Heat, vibration, imbalance

Repair cost: Moderate to high

Overheating risk: Moderate (unless imbalance exists)

How to Diagnose Which Motor Type Is Failing

For single-phase motors:

- Check capacitors first

- Inspect centrifugal switch

- Measure insulation resistance

- Verify cooling airflow

For three-phase motors:

- Measure phase voltage and current

- Check balance (≤1–2%)

- Inspect bearings

- Review VFD settings if applicable

Electrical measurements usually tell the story quickly.

Common Misdiagnoses

Replacing capacitors when windings are already damaged

Rewinding motors when bearings are the real problem

Ignoring voltage imbalance

Assuming VFD failures are “bad motors”

Oversizing replacement motors instead of fixing root causes

When Repair Makes Sense

Single-phase motors:

- Capacitor or switch failure

- Bearings in good condition

- Windings test healthy

Three-phase motors:

- Bearing-only failure

- No insulation damage

- Critical or specialty motor

When Replacement Makes More Sense

Single-phase motors:

- Winding failure on small motors

- Repeated electrical issues

- Obsolete designs

Three-phase motors:

- Severe insulation breakdown

- Core damage

- Non-critical standard motors

Final Takeaway

Single-phase motors usually fail due to starting components and heat, while three-phase motors fail due to voltage imbalance, bearings, and VFD-related stress. Knowing the difference speeds diagnosis, reduces downtime, and prevents unnecessary repairs.

The fastest fix is almost always identifying how that motor type typically fails — before guessing.