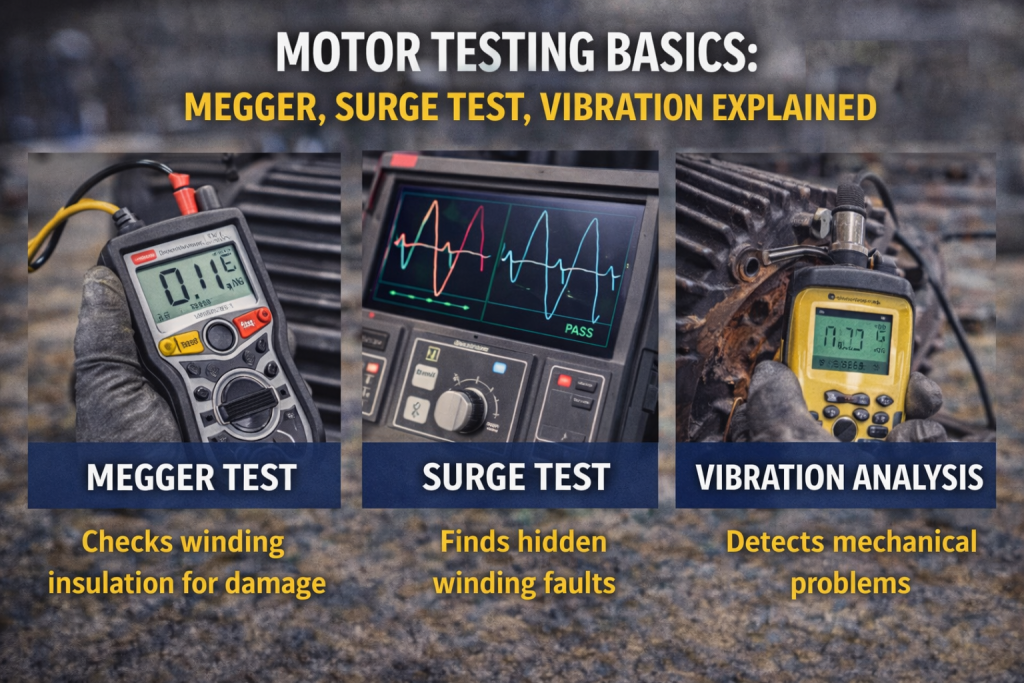

When a motor starts acting up, proper testing tells you what’s actually wrong — not just what failed last time. Three tests show up again and again in motor repair shops: megger testing, surge testing, and vibration analysis.

Each one answers a different question. Together, they prevent guesswork, unnecessary rewinds, and repeat failures.

This guide explains what each test does, what it tells you, and when it matters — without turning it into an engineering textbook.

Why Motor Testing Matters

Motor testing helps you:

- Identify electrical vs mechanical problems

- Catch failures early

- Avoid unnecessary rewinds

- Prevent repeat breakdowns

- Make repair vs replace decisions confidently

No single test tells the whole story. Each test looks at a different failure mode.

Megger Test: “Is the Insulation Still Good?”

A megger test checks insulation resistance between motor windings and ground.

In simple terms, it answers:

“Is electricity staying where it belongs?”

What the Megger Test Detects

- Moisture contamination

- Insulation aging

- Ground faults

- Dirt or oil intrusion

- Early winding breakdown

How It Works (Simply)

A high DC voltage is applied to the windings. The megger measures how much current leaks through insulation.

More leakage = worse insulation.

What Results Mean

- High resistance: Insulation is healthy

- Low resistance: Insulation is compromised

- Rapid drop: Serious insulation damage

What Megger Does Not Detect

- Turn-to-turn shorts

- Bearing problems

- Mechanical issues

Megger tests are quick and essential, but they don’t tell the full winding story.

Surge Test: “Are the Windings Shorting Internally?”

A surge test looks for turn-to-turn insulation failure — one of the most destructive motor problems.

This test answers:

“Are the coils inside the motor electrically identical?”

What the Surge Test Detects

- Turn-to-turn shorts

- Weak coil insulation

- Manufacturing defects

- Rewind quality issues

How It Works (Simply)

Each phase is hit with a fast voltage pulse. The tester compares electrical waveforms between phases.

Matching waveforms = healthy windings

Mismatch = internal short or weakness

Why Surge Testing Is Critical

- Many motors pass megger tests but fail surge tests

- Surge testing catches failures before they trip breakers

- It’s the best way to verify rewind quality

What Surge Tests Don’t Detect

- Bearing wear

- Shaft alignment issues

- Cooling problems

Surge testing is one of the most powerful predictive tools for winding failure.

Vibration Analysis: “Is Something Moving That Shouldn’t Be?”

Vibration testing focuses on mechanical health, not electrical condition.

This test answers:

“Is the motor running smoothly?”

What Vibration Testing Detects

- Bearing wear

- Misalignment

- Imbalance

- Mechanical looseness

- Resonance issues

How It Works (Simply)

Sensors measure vibration frequency and amplitude while the motor runs.

Different vibration patterns point to different mechanical problems.

Common Vibration Clues

- Low-frequency vibration: Imbalance

- High-frequency vibration: Bearing damage

- Directional vibration: Misalignment

- Increasing trend: Failure is developing

What Vibration Testing Doesn’t Detect

- Insulation breakdown

- Electrical shorts

- Voltage issues

Vibration testing is often the earliest warning sign of bearing failure.

How These Tests Work Together

Each test answers a different question:

Megger → insulation to ground

Surge → insulation between coils

Vibration → mechanical condition

Used together, they eliminate guesswork.

Example scenarios:

- Good megger + bad surge → winding failure starting

- Bad vibration + good electrical tests → bearing or alignment issue

- All tests good → problem likely external (load, voltage, cooling)

Common Testing Mistakes We See

Skipping surge tests because megger “passed”

Assuming noise always means bearings

Testing only after failure instead of trending

Ignoring test history

Treating tests as pass/fail instead of diagnostic tools

Testing works best when results are tracked over time.

When Each Test Matters Most

Megger testing matters when:

- Motors have been idle

- Moisture exposure is suspected

- After washing or flooding

- Before startup

Surge testing matters when:

- Motors are rewound

- Repeat winding failures occur

- VFDs are involved

- Reliability is critical

Vibration testing matters when:

- Motors run continuously

- Bearings are critical

- Predictive maintenance is used

- Noise or heat is present

Final Takeaway

Megger, surge, and vibration tests don’t compete — they complement each other. Megger checks insulation health, surge testing reveals internal winding weakness, and vibration analysis exposes mechanical problems before they cause damage.

Understanding what each test actually tells you leads to smarter repairs, fewer failures, and longer motor life.