Flap discs are one of the most versatile grinding and finishing tools in a shop—but only if the grit matches the job. Using the wrong grit wastes time, overheats metal, burns stainless, and leaves extra cleanup work behind.

At CEM Industrial Supply in Coldwater, Michigan, flap disc selection is one of the most common “why does this look terrible?” conversations we have. Once you understand what each grit actually does, flap discs become predictable, fast, and clean.

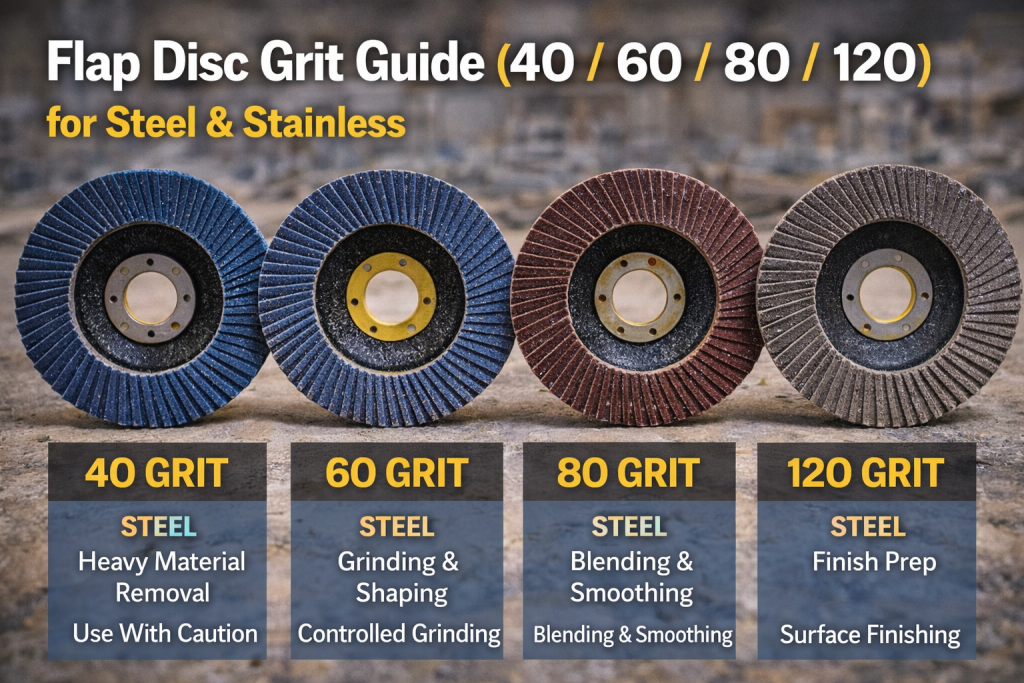

This guide breaks down 40, 60, 80, and 120 grit flap discs, when to use each one, and how they behave on steel vs stainless.

How Flap Disc Grit Actually Works

Flap disc grit refers to abrasive coarseness:

- Lower numbers = more aggressive material removal

- Higher numbers = finer finish and better control

Flap discs grind and blend at the same time, unlike hard grinding wheels that only remove material.

Choosing grit is about how much material you want to remove vs how clean you want the finish.

40 Grit Flap Discs: Heavy Stock Removal

40 grit flap discs are aggressive and fast-cutting. They remove material quickly but leave a rough finish.

Best used for:

- Heavy weld removal

- Beveling plate

- Removing mill scale

- Structural steel prep

- Thick steel fabrication

Steel performance:

- Excellent cutting speed

- Fast weld knockdown

- Leaves deep scratch pattern

Stainless performance:

- Use with caution

- Easy to overheat

- Can discolor or gouge stainless

40 grit is for shaping, not finishing.

60 Grit Flap Discs: Controlled Grinding

60 grit flap discs balance removal speed with control. This is one of the most commonly used grits in fabrication.

Best used for:

- Weld blending

- Moderate stock removal

- Edge cleanup

- General-purpose grinding

Steel performance:

- Strong cutting action

- More control than 40 grit

- Easier to clean up afterward

Stainless performance:

- Good for weld blending

- Lower heat than 40 grit

- Still requires light pressure

If you only carry one aggressive flap disc, 60 grit is usually the safest choice.

80 Grit Flap Discs: Blending and Smoothing

80 grit flap discs are designed for smoothing, blending, and surface refinement.

Best used for:

- Weld blending before finishing

- Surface smoothing

- Reducing scratch depth

- Preparing for paint or coating

Steel performance:

- Clean blending

- Minimal gouging

- Easier finish prep

Stainless performance:

- Excellent for controlled blending

- Reduced heat buildup

- Cleaner visual finish

80 grit is the transition grit between grinding and finishing.

120 Grit Flap Discs: Finishing and Surface Prep

120 grit flap discs are finishing tools. They remove minimal material and focus on surface appearance.

Best used for:

- Final surface prep

- Stainless finishing

- Paint and powder coat prep

- Light deburring

Steel performance:

- Smooth finish

- Minimal material removal

- Ideal before coatings

Stainless performance:

- Best choice for cosmetic work

- Lower risk of burning

- Consistent finish direction

120 grit is not for removing welds—it’s for making work look finished.

Steel vs Stainless: Critical Differences

Steel is forgiving. Stainless is not.

When working stainless:

- Use lighter pressure

- Keep discs moving

- Avoid excessive heat

- Step through grits instead of jumping

Burned stainless is permanent and usually requires rework.

Grit Progression: The Right Way

For best results:

- Heavy removal: 40 → 60

- Weld blending: 60 → 80

- Finish prep: 80 → 120

Skipping grits saves time upfront but costs time fixing deep scratches later.

Common Flap Disc Mistakes

At CEM Industrial Supply, these mistakes cause most problems:

- Using 40 grit for finishing

- Pressing too hard

- Using worn discs past their effectiveness

- Using steel-rated discs on stainless

- Running grinders at excessive angles

Let the abrasive do the work.

Choosing the Right Flap Disc

40 grit: Fast removal, rough finish

60 grit: Balanced grinding and control

80 grit: Blending and smoothing

120 grit: Finishing and prep

Match the grit to the goal—not the impatience.

Get the Right Abrasives for the Job

At CEM Industrial Supply in Coldwater, Michigan, we stock flap discs for steel, stainless, and mixed-metal work—and we help customers choose the grit that actually works. If your finish looks wrong or work feels slow, the disc—not the grinder—is usually the issue.

Stop in or call and get set up right.

Frequently Asked Questions

Can I use steel flap discs on stainless?

Only if they are rated for stainless. Otherwise, contamination can occur.

Is higher grit always better?

No. Higher grit removes less material and won’t fix heavy welds.

Why does stainless turn blue or brown?

Excessive heat from pressure or coarse grit.

How long should a flap disc last?

Until cutting slows significantly—then replace it.