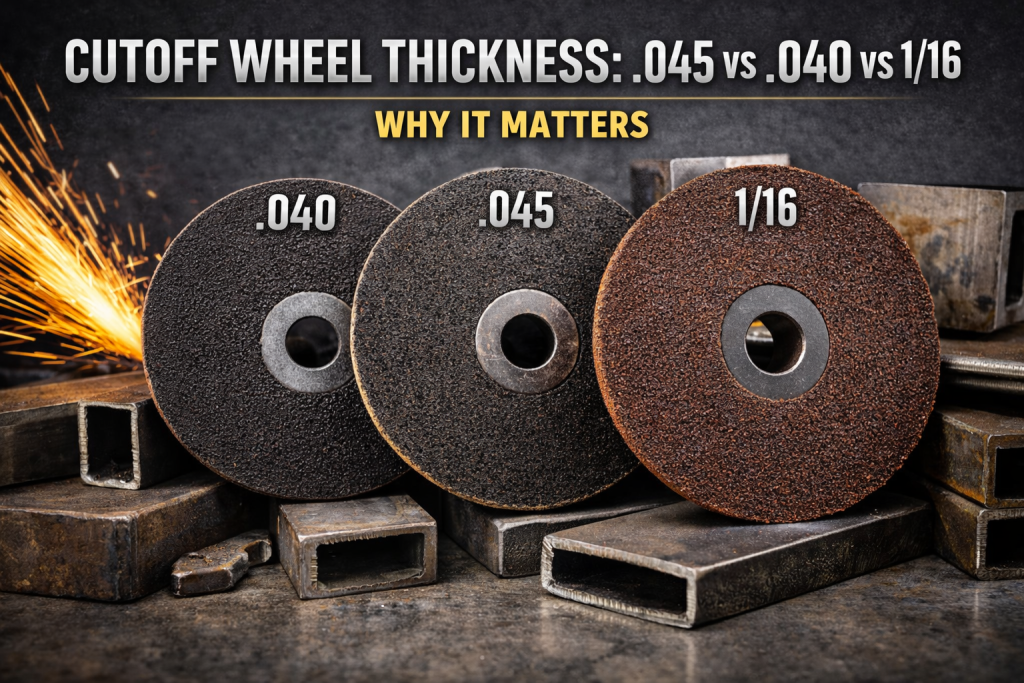

Cutoff wheels may look similar on the shelf, but thickness makes a huge difference in how fast you cut, how clean the edge is, and how often you’re swapping wheels. Choosing between .045, .040, and 1/16 cutoff wheels isn’t just preference — it directly affects performance, safety, and cost per cut.

This guide explains what each cutoff wheel thickness is best for, when it makes sense to go thinner, and when thicker is actually the smarter choice.

Why Cutoff Wheel Thickness Matters

Cutoff wheel thickness affects:

- Cutting speed

- Heat buildup

- Material loss (kerf width)

- Wheel life

- Control and stability

- Risk of binding or breakage

Using the wrong thickness usually shows up as slow cuts, overheated metal, wandering cuts, or wheels wearing out faster than expected.

.045 Cutoff Wheels: The Balanced Standard

.045-inch cutoff wheels are the most common thickness and a true all-around option. They balance cutting speed, durability, and control, making them ideal for everyday shop and jobsite use.

Best uses:

- Mild steel

- Carbon steel

- Tubing

- Angle iron

- Flat stock

Strengths:

- Good balance of speed and life

- More forgiving than ultra-thin wheels

- Easier to control on handheld grinders

- Lower breakage risk

Limitations:

- Slightly slower than .040 on thin materials

- More material loss than thinner wheels

If you’re only stocking one cutoff wheel thickness, .045 is usually the safest and most versatile choice.

.040 Cutoff Wheels: Faster, Cleaner Cuts

.040-inch cutoff wheels are thinner, which means less resistance and faster cutting. They remove less material and generate less heat, making them excellent for precision work.

Best uses:

- Thin wall tubing

- Sheet metal

- Stainless steel

- Clean, accurate cuts

Strengths:

- Faster cut speed

- Narrower kerf

- Cleaner edge

- Reduced heat buildup

Limitations:

- Shorter lifespan

- Requires better control

- Higher breakage risk if twisted or forced

.040 wheels shine when speed and cut quality matter more than wheel longevity. They’re popular in fabrication shops doing repetitive, precise cuts.

1/16 Cutoff Wheels: Durability and Stability

1/16-inch cutoff wheels are thicker and more rigid. They’re slower, but they hold up better under pressure and are less likely to flex or shatter.

Best uses:

- Heavy stock

- Solid bar

- Thick steel

- Demolition or rough cutting

Strengths:

- Longer wheel life

- Better stability

- Lower risk of wheel deflection

- More forgiving for less experienced users

Limitations:

- Slower cutting

- Wider kerf

- More heat buildup

When control and durability matter more than speed, 1/16 wheels are often the better choice.

Side-by-Side Comparison

.040 Thickness

Best for: Thin materials, clean cuts

Cut speed: Fastest

Wheel life: Shorter

Control required: High

.045 Thickness

Best for: General purpose cutting

Cut speed: Fast

Wheel life: Balanced

Control required: Moderate

1/16 Thickness

Best for: Thick or heavy material

Cut speed: Slower

Wheel life: Longest

Control required: Low

Common Mistake: Thinner Isn’t Always Better

A common misconception is that thinner cutoff wheels are always superior. In reality, ultra-thin wheels fail early when used on thick stock or when side pressure is applied. That leads to higher wheel consumption and safety risks.

Matching wheel thickness to material thickness and cutting technique is far more important than choosing the thinnest option available.

Safety Considerations

- Always match wheel RPM rating to your grinder

- Never side-load a cutoff wheel

- Use steady, straight cuts

- Let the wheel do the work — don’t force it

- Replace wheels showing cracks or excessive wear

Thinner wheels demand better technique. Thicker wheels offer more margin for error.

Final Takeaway

Cutoff wheel thickness directly affects speed, control, safety, and cost per cut. .040 wheels cut fastest and cleanest, .045 wheels offer the best all-around performance, and 1/16 wheels provide durability and stability for heavier work.

If you’re unsure which cutoff wheel thickness fits your application, talk to us — we’ll help match the right wheel to your material and cutting style so you get better results with fewer wheel changes.