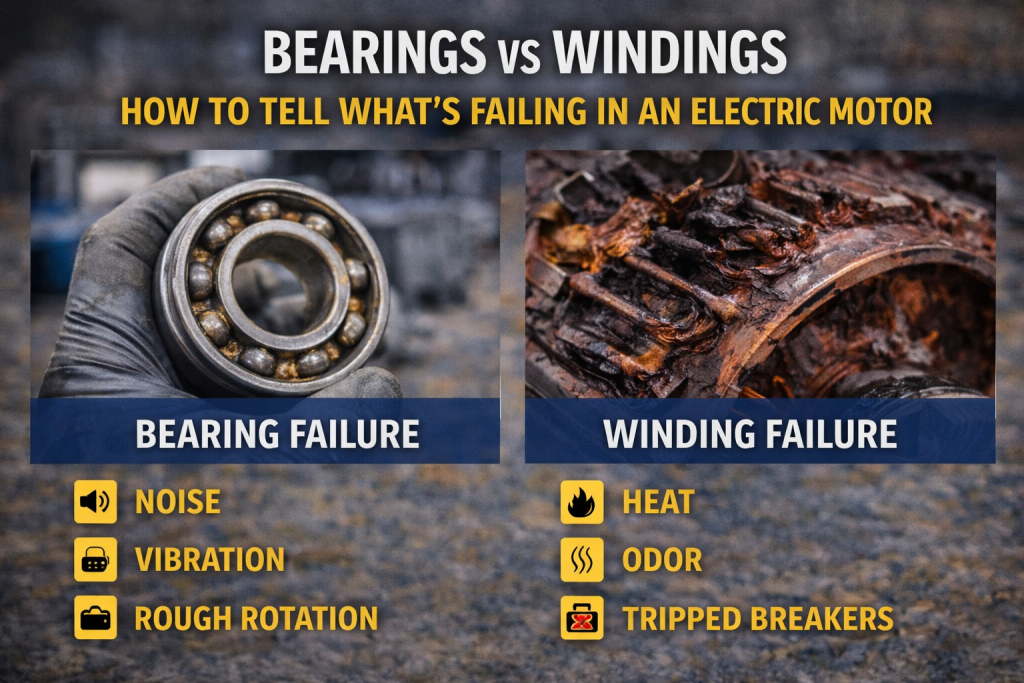

When a motor starts making noise, running hot, or tripping breakers, the big question is always the same: is it a bearing problem or a winding problem?

Getting this wrong leads to wasted repairs, unnecessary rewinds, or motors being replaced when they could’ve been saved.

This guide shows how to tell bearing failure from winding failure, what symptoms matter most, and what to check first before the motor is permanently damaged.

Why This Distinction Matters

Bearings and windings fail differently — and the fix is very different.

Bearing failure usually means:

- Mechanical repair

- Lower cost

- Faster turnaround

Winding failure often means:

- Electrical repair or rewind

- Higher cost

- Longer downtime

Catching the right problem early can be the difference between a bearing change and a full rewind.

Symptoms That Point to Bearing Failure

Bearing problems usually announce themselves loudly — sometimes literally.

Common bearing symptoms:

- Grinding, growling, or rumbling noise

- Squealing or chirping sounds

- Excessive vibration

- Heat concentrated at the bearing housings

- Shaft play or rough rotation

- Noise that changes with speed, not load

What to check first:

- Spin the shaft by hand (power off)

- Listen with a mechanic’s stethoscope

- Check bearing temperature

- Inspect grease condition and quantity

If the motor sounds bad but still runs electrically normal, bearings are the prime suspect.

Symptoms That Point to Winding Failure

Winding problems are quieter — but far more destructive.

Common winding symptoms:

- Tripped breakers or overloads

- Burnt electrical smell

- Discolored windings

- Excessive current draw

- Uneven phase amperage

- Reduced torque or slow startup

- Motor runs hot with no mechanical load

What to check first:

- Measure phase current and balance

- Perform insulation resistance (megger) testing

- Check for voltage imbalance

- Inspect for moisture contamination

If electrical readings are off, or insulation tests fail, the problem is almost always internal to the windings.

Noise vs Heat: A Quick Rule of Thumb

Noise-driven problem → Bearings

Current-driven problem → Windings

This isn’t foolproof, but it’s a solid starting point.

How Bearings and Windings Fail Together

One failure often leads to the other.

Bearing failure causes:

- Increased friction

- Higher operating temperatures

- Accelerated insulation breakdown

Winding failure causes:

- Electrical imbalance

- Magnetic vibration

- Excess stress on bearings

This is why delaying repair usually turns a simple bearing job into a rewind.

Tests That Separate Bearing vs Winding Issues

Bearing-focused checks:

- Vibration analysis

- Acoustic testing

- Shaft runout inspection

- Grease inspection

Winding-focused checks:

- Insulation resistance testing

- Surge comparison testing

- Phase resistance testing

- Current imbalance measurement

A proper diagnosis usually includes both mechanical and electrical testing.

Common Misdiagnoses We See

Replacing bearings when windings are already damaged

The motor fails again shortly after restart.

Assuming noise always means bearings

Electrical imbalance can cause magnetic noise that mimics bearing failure.

Ignoring early warning signs

Heat and vibration don’t fix themselves.

When Bearings Are the Only Problem

Bearings are likely the only issue when:

- Electrical readings are normal

- Insulation tests pass

- Noise is the main complaint

- Motor hasn’t overheated significantly

This is the best-case scenario and usually a straightforward repair.

When Windings Are Already Failing

Windings are likely compromised when:

- Insulation resistance is low

- Motor trips under normal load

- Burnt odor is present

- History of overheating exists

- Voltage imbalance has gone unchecked

At this point, bearing replacement alone won’t save the motor.

What to Check First (Quick Diagnostic Order)

- Listen and feel for mechanical roughness

- Measure phase current and balance

- Check bearing temperatures

- Perform insulation resistance testing

- Review motor load and voltage history

This sequence catches the most common failures efficiently.

Final Takeaway

Bearing failures are mechanical, noisy, and often repairable. Winding failures are electrical, heat-driven, and far more expensive if ignored. The key is identifying which system is failing before secondary damage occurs.

If a motor feels wrong, sounds wrong, or runs hot, the sooner it’s checked, the more likely it can be saved.