If you’ve ever had a sanding belt glaze over, turn black, or start burning the workpiece instead of cutting it, the problem usually isn’t the sander — it’s the belt type. Aluminum oxide and zirconia sanding belts behave very differently under pressure, speed, and heat.

This guide explains the real differences between aluminum oxide and zirconia sanding belts, what causes belts to burn, and how to choose the right belt so you’re sanding efficiently instead of fighting friction.

Why Sanding Belt Choice Matters

Sanding belts affect:

- Cut speed

- Heat buildup

- Surface finish

- Belt life

- Risk of burning or glazing

Using the wrong belt often leads to scorched metal, clogged belts, inconsistent finishes, and constant belt changes.

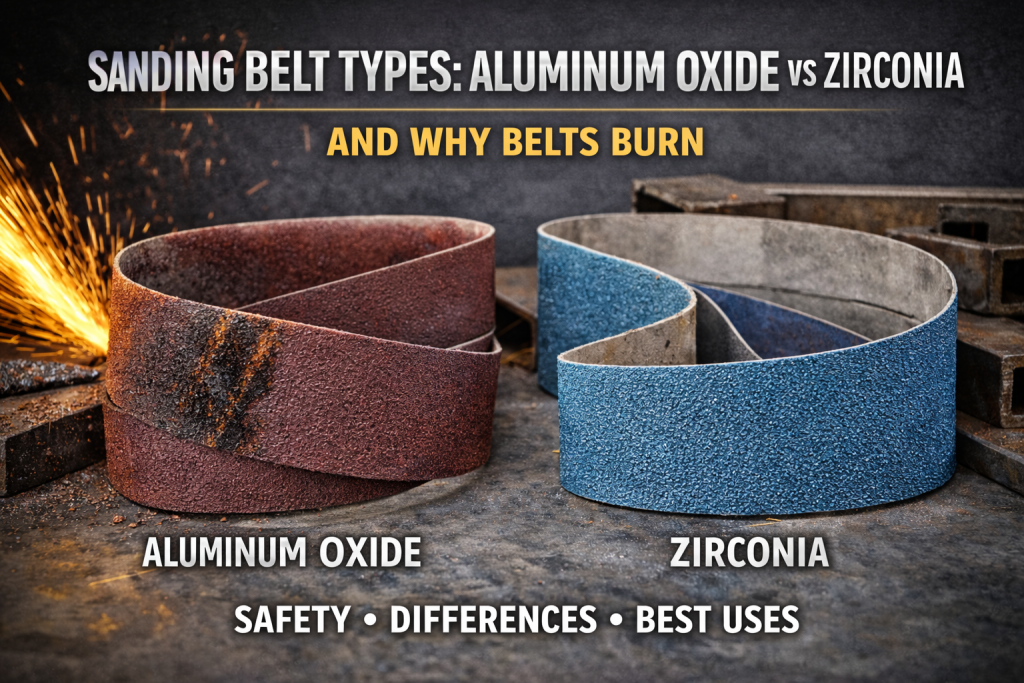

Aluminum Oxide Sanding Belts: General Purpose, Light Pressure

Aluminum oxide is the most common sanding belt abrasive. It’s tough, affordable, and works well for lighter-duty sanding where pressure and heat are controlled.

Best uses:

- Wood sanding

- Mild steel

- Aluminum

- Paint and coating removal

- Light surface prep

Strengths:

- Lower cost

- Smooth, predictable finish

- Good for variable materials

- Easy to control

Limitations:

- Dulls faster under heavy pressure

- Generates heat quickly

- More prone to glazing

- Shorter belt life on metal

Aluminum oxide belts are ideal for woodworking and light metal work, but they struggle when pushed hard or run continuously on steel.

Zirconia Sanding Belts: Aggressive and Heat-Resistant

Zirconia alumina sanding belts are engineered to fracture and expose fresh cutting edges as they wear. They are designed for heavy pressure and continuous metal sanding.

Best uses:

- Steel fabrication

- Stainless steel

- Weld blending

- Deburring

- Production sanding

Strengths:

- Faster cut rate

- Runs cooler

- Longer belt life

- Self-sharpening grain

- Excellent under pressure

Limitations:

- Higher upfront cost

- Less effective at very light pressure

- Overkill for wood

Zirconia belts perform best when you lean into the work. Light pressure doesn’t allow the grain to fracture properly, which can reduce effectiveness.

Why Sanding Belts Burn

Burning happens when friction replaces cutting. Common causes include:

Wrong abrasive grain

Using aluminum oxide on heavy steel or stainless creates heat faster than it can shed, leading to burn marks and glazing.

Too much pressure

Pressing harder doesn’t always cut faster. Excess pressure flattens grains and creates friction.

Wrong belt speed

Running belts too fast increases heat buildup, especially on metal.

Clogged or glazed belts

Once a belt loads up with material, it stops cutting and starts rubbing.

Dull belts

A worn belt generates heat instead of removing material.

How to Prevent Burning

Choose the right grain

Use zirconia for heavy metal sanding and aluminum oxide for lighter work.

Use steady pressure

Let the abrasive do the work — don’t force it.

Watch belt speed

Slower speeds reduce heat and improve control on metal.

Change belts early

Pushing a worn belt always costs more time and material damage than replacing it.

Use proper grit progression

Jumping grits creates extra heat and uneven finishes.

Side-by-Side Comparison

Aluminum Oxide

Best for: Wood, light metal, coatings

Heat resistance: Lower

Belt life: Shorter

Cost: Lower

Zirconia

Best for: Steel, stainless, welds

Heat resistance: High

Belt life: Longer

Cost: Medium

Common Mistake: Using One Belt for Everything

Many shops try to use aluminum oxide belts for all sanding tasks. On steel, this almost always leads to burning, short belt life, and frustration. Switching to zirconia for metal work usually cuts sanding time in half and reduces belt changes.

Final Takeaway

Aluminum oxide sanding belts are great for lighter-duty sanding and wood, while zirconia belts excel at heavy metal sanding and resist burning under pressure. If your belts are burning, glazing, or wearing out fast, the solution is usually switching belt type — not sanding harder.

If you’re unsure which sanding belt fits your application, ask us — we’ll help match the belt to the material so you get clean cuts without heat damage.