Drilling into concrete, block, or masonry is where a lot of tools get abused—and a lot of holes go nowhere. The most common mistake isn’t using a dull bit. It’s using the wrong type of drill entirely.

At CEM Industrial Supply in Coldwater, Michigan, we regularly see customers burn up hammer drills trying to do rotary hammer work, or overspend on rotary hammers when a hammer drill would have done the job just fine. Understanding the difference saves time, money, and frustration.

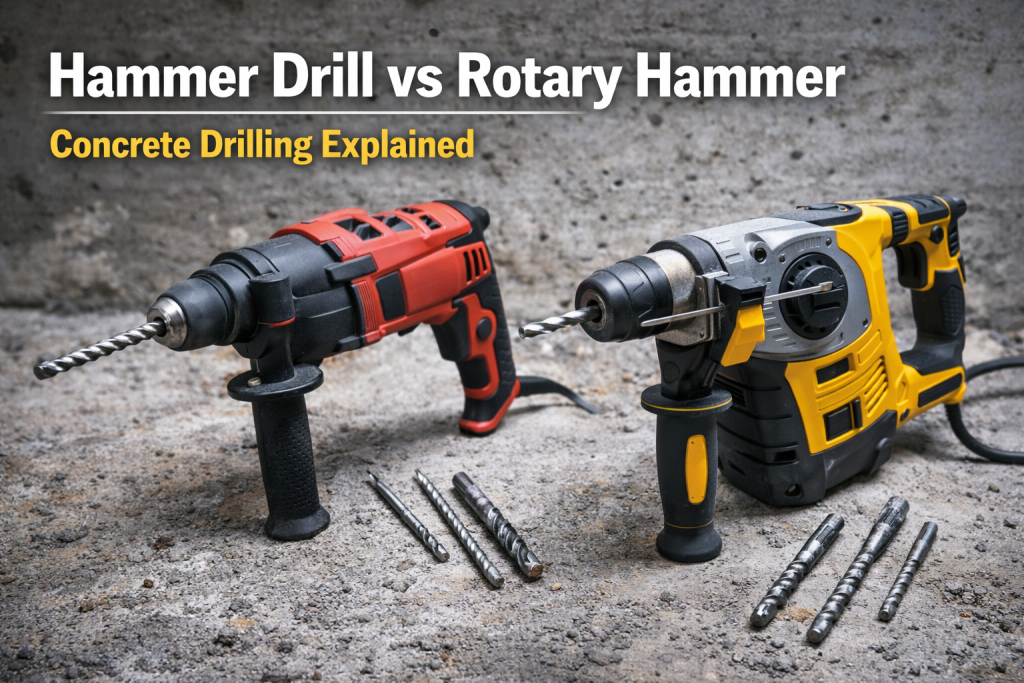

Here’s a clear explanation of hammer drills vs rotary hammers, what each one is designed to do, and which one you actually need.

What a Hammer Drill Is Designed to Do

A hammer drill looks similar to a standard drill, but it adds a light hammering action to help the bit chip into masonry. The hammering comes from two ridged discs inside the drill that vibrate as the drill spins.

Hammer drills are best for:

- Light-duty concrete drilling

- Brick and block

- Anchors and fasteners

- Small-diameter holes

- Occasional masonry work

Typical applications include Tapcon screws, small anchors, and mounting hardware in block or poured concrete.

Hammer drills rely on rotation first, hammering second. That means progress slows significantly as hole size increases or concrete gets harder.

Limitations of Hammer Drills

Hammer drills struggle when:

- Hole diameter increases

- Concrete contains aggregate or rebar

- Multiple holes are required

- Drilling depth increases

This is where users start leaning on the tool, overheating bits, and burning out motors.

What a Rotary Hammer Is Designed to Do

A rotary hammer is built specifically for masonry and concrete work. Instead of vibrating discs, it uses a piston-driven hammer mechanism that delivers much more impact energy directly into the bit.

Rotary hammers are best for:

- Medium to heavy concrete drilling

- Large-diameter holes

- Repeated drilling

- Structural concrete

- Chipping and light demolition (on some models)

If you drill concrete regularly, a rotary hammer isn’t a luxury—it’s the correct tool.

SDS Plus vs SDS Max Explained

Rotary hammers use specialized bit systems.

SDS Plus:

- Most common

- Ideal for anchors and general concrete drilling

- Lighter and more maneuverable

SDS Max:

- Larger and heavier

- Designed for big holes and demolition

- Used in commercial and industrial applications

Trying to use standard masonry bits in a rotary hammer defeats the purpose of the tool.

Hammer Drill vs Rotary Hammer: Real-World Differences

Hammer drills rely on speed and pressure. Rotary hammers rely on impact force. That’s why a rotary hammer drills faster with less effort, less heat, and less wear on the bit.

If drilling feels like work, the tool is probably wrong.

Common Concrete Drilling Mistakes

At CEM Industrial Supply, these mistakes cause most failures:

- Using a hammer drill for repeated concrete drilling

- Using dull or incorrect bits

- Applying excessive pressure instead of letting the tool work

- Ignoring dust and heat buildup

- Using standard drill bits instead of SDS bits

Most concrete drilling problems are solved by switching tools—not pushing harder.

Corded vs Cordless Considerations

Cordless hammer drills are convenient for light anchoring work. Cordless rotary hammers are increasingly popular for mobility, but corded rotary hammers still dominate long-duration and heavy-duty drilling.

The tool type matters more than the power source.

Which One Should You Buy?

Choose a hammer drill if:

- You drill occasional small holes

- Hole size is under 3/8 inch

- Work is light and infrequent

Choose a rotary hammer if:

- You drill concrete regularly

- Hole sizes exceed 3/8 inch

- You’re anchoring into structural concrete

- Speed and efficiency matter

Buying the right tool once is cheaper than replacing burned-out drills.

Get the Right Tool for Concrete Drilling

At CEM Industrial Supply in Coldwater, Michigan, we help contractors, maintenance teams, and serious DIYers choose the right drilling tools and bits for concrete and masonry. If drilling feels harder than it should, the tool—not the operator—is usually the problem.

Stop in or call and get set up correctly the first time.

Frequently Asked Questions

Can a hammer drill drill into concrete?

Yes, but only for light-duty work and smaller holes.

Why does a rotary hammer drill faster?

Its piston-driven hammer mechanism delivers far more impact energy directly into the bit.

Do I need SDS bits for a rotary hammer?

Yes. SDS bits are required to transfer impact force properly.

Is a rotary hammer overkill for anchors?

For occasional anchors, yes. For repeated anchoring, no.