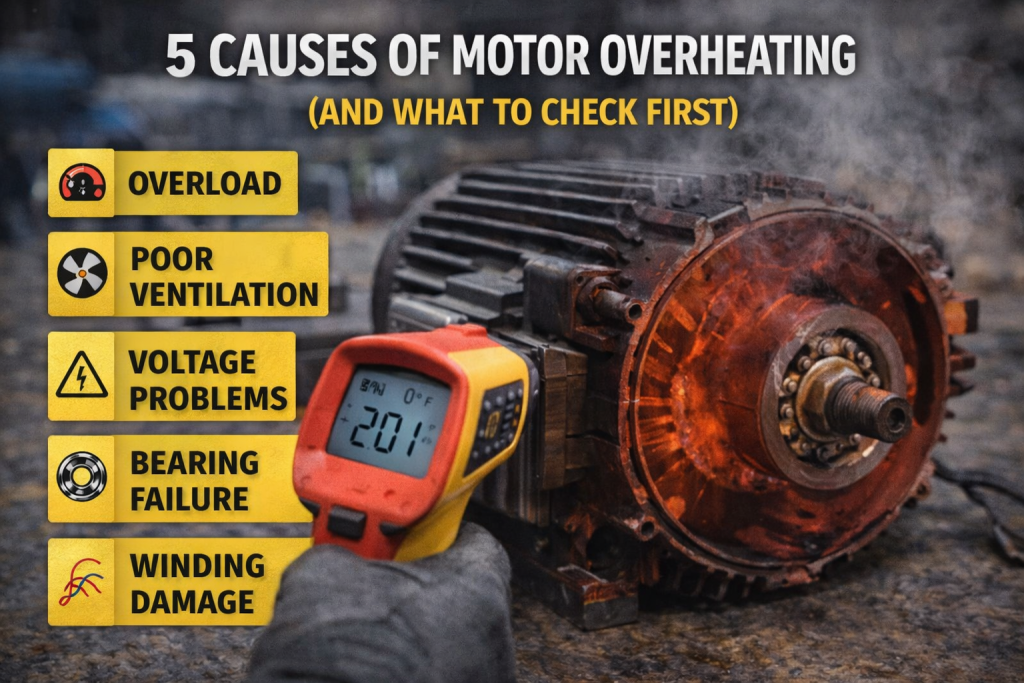

Motor overheating is one of the most common reasons motors fail — and in many cases, it’s preventable. When a motor runs too hot, insulation breaks down, bearings fail, and windings deteriorate long before the motor ever stops turning.

This guide covers the five most common causes of motor overheating, what symptoms to look for, and what you should check first before permanent damage occurs.

Why Motor Overheating Is Serious

Excessive heat:

- Breaks down winding insulation

- Shortens bearing life

- Causes premature motor failure

- Increases energy consumption

- Leads to unplanned downtime

A motor can overheat for weeks before it fails catastrophically. Catching the cause early often saves the motor.

1. Overloading the Motor

Overloading is the number one cause of overheating.

Common overload causes:

- Driven equipment binding or seizing

- Increased process demand

- Incorrect motor sizing

- Mechanical drag

- Worn bearings or belts

What to check first:

- Measure motor amperage under load

- Compare readings to nameplate FLA

- Inspect driven equipment for resistance

If the motor is pulling more current than rated, heat buildup is inevitable.

2. Poor Ventilation or Cooling Airflow

Motors rely on airflow to remove heat. Restricted airflow causes temperatures to rise quickly.

Common airflow issues:

- Blocked cooling vents

- Dirt, dust, or grease buildup

- Damaged or missing cooling fan

- Motor mounted in confined spaces

What to check first:

- Inspect air vents and cooling fins

- Verify fan rotation and condition

- Check clearance around the motor

Even a properly sized motor will overheat if it cannot shed heat.

3. Voltage Problems (Too High, Too Low, or Unbalanced)

Electrical supply issues create excess heat inside the windings.

Common voltage problems:

- Low voltage increases current draw

- High voltage increases core losses

- Voltage imbalance causes uneven heating

- Single-phasing on three-phase motors

What to check first:

- Measure line voltage at the motor terminals

- Check phase balance (should be within 1–2%)

- Inspect connections and contactors

Voltage imbalance as low as 3% can increase winding temperature by over 20%.

4. Bearing Problems

Failing bearings create friction, which translates directly into heat.

Common bearing issues:

- Lack of lubrication

- Over-greasing

- Contaminated grease

- Misalignment

- Worn or damaged bearings

What to check first:

- Listen for unusual noise

- Check bearing temperature

- Inspect grease condition and quantity

Bearing failures often masquerade as electrical problems, but the heat source is mechanical.

5. Winding or Insulation Damage

Internal electrical damage causes localized heating inside the motor.

Common causes:

- Aged insulation

- Previous overheating events

- Moisture ingress

- Ground faults

- Partial shorts

What to check first:

- Perform insulation resistance (megger) testing

- Look for discoloration or burnt odor

- Review motor repair or rewind history

Once insulation begins to fail, overheating accelerates rapidly.

What to Check First: A Quick Diagnostic Order

If a motor is running hot, start here:

- Measure amperage under load

- Inspect ventilation and cleanliness

- Check voltage balance and supply

- Listen and feel for bearing issues

- Test insulation resistance

This sequence catches the most common and least expensive problems first.

Common Mistakes We See

Ignoring nameplate ratings

Motors are designed to operate within specific limits.

Assuming heat is “normal”

Warm is normal. Hot enough to burn is not.

Continuing to run overheated motors

Each overheating cycle permanently damages insulation.

Treating symptoms instead of causes

Cooling fans don’t fix overloads or voltage problems.

When Overheating Means Repair or Rewind

Overheating often indicates the need for:

- Bearing replacement

- Electrical repair

- Insulation restoration

- Full motor rewind

A professional inspection determines whether the motor can be saved or should be replaced.

Final Takeaway

Motor overheating is almost always caused by overload, cooling issues, voltage problems, bearing failure, or winding damage. Checking amperage, airflow, voltage, and bearings first can prevent costly failures and downtime.

If a motor feels hotter than usual, it’s telling you something — and ignoring it is usually the most expensive option.